Multiple agricultural machineries

Janak Santi

Normally from sowing to harvesting of any crop, about 10 – 15 different implements are needed. Keeping this view in consideration, Amurutbhai developed “Janak Santi” way back in the year 1972. This agricultural device, made of cast iron, can be used in all types of crop and soil. In this implement near about 15 subsidiary implements can be attached for carrying out different agricultural operations.

Mini Kaliu (Groundnut digger, 1980)

Normally in Saurashtra severe drought condition occurs, due to this the soil of this region has become very hard. Groundnut is an important cash crop of this region, but when the harvesting of groundnut coincides with drought condition it becomes a laborious and time-consuming process. Keeping this in view, Amrutbhai developed the Mini Kaliu, which is exclusively used for the harvesting of the groundnut crop under severe drought condition. It is a simple twin bullock drawn implement, which is used to dig out the groundnut in hard soil condition. The implement is made up of cast iron weighing about 30 to 35 kg. The length of beam is 40 inches, which rests on two supporting wheels. These wheels help the attached blade to penetrate in the soil uniformly and easily. The thrusting of blade to a particular depth in the soil can be adjusted with this implement. Different length blades are available, which can be used accordingly.

This device, which can be used easily by one or two persons, reduces time and labour and improves the harvesting rate. Amurutbhai sold over 250 mini kaliu in the Saurashtra and surrounding region.

The Wheat Sowing Box (1984)

Normally in Saurashtra region, wheat sowing is done by using narrow coulters of 2” - 3.5” width on a harrow. In this method, the plants grow close to each other within the narrow row and the space between the two rows within a furrow remains more or less vacant leading to ineffective absorption of moisture and nutrients. Sometimes sowing is done by hands where the moisture absorption is better but the plants, which grow on other edge of the furrow, tend to lodge on maturity as the seeds did not penetrate deep enough.

To solve these problems, in mid 1990s, Amrutbhai, after many trials, came up with a wheat sowing box for equal and uniform distribution of wheat seeds in the farms. The farmers liked it, replicated it and benefited from it. Word spread from mouth to mouth and this small device got copied but Amrutbhai did not complain.

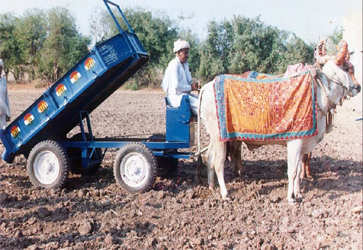

Aaruni Bullock Cart: Tilting Cart & Bullocks' Blessing (1995)

Although there is much variation in size, structure and the materials used in the Indian bullock-cart, the basic design has been the same for hundreds of years. The traditional bullock cart has only two wheels. Consequently part of the load is borne by the draft animals on their shoulders/necks. Hence the animals’ work consists not only of pulling the cart but also of supporting part of the load. Another shortcoming in the design is the harnessing system, which makes it difficult to negotiate sharp bends or turns in the road. As a result of these limitations, bullocks often develop galls on their necks and suffer silently as they toil for their masters. All this affects not only the efficiency of the animals but also their stamina. For several years, Amrutbhai had been concerned about this “erosion of strength” of draft animals.

A major issue bothering Amrutbhai was the waste of labour, which again stems from the limitations of the existing design. In the Junagadh region, farmers make organic compost from agricultural waste, animal waste and ‘tas’, a mineral-rich soil excavated from wastelands or common property lands. They transport it to the fields in bullock-carts. The actual application of the compost in the furrows was done usually by the women folk. Since the compost had to be applied in summer before the onset of monsoon, the women had to toil under the scorching sun and distribute the manure with baskets. Amrutbhai often discussed this problem with the farmers who came to his workshop for repair of implements or purchase of new ones. It was through these discussions that he conceived the idea of a bullock-cart which would be similar to a tractor with a hydraulic system for lifting the trolley. In such a system the body of the cart would be tilted gradually so that the compost fell directly into the furrows, in a uniform manner. The new cart would have four wheels and a harness rotating devise which would enable the bullocks to negotiate sharp bends more easily. Although the idea was attractive, developing a prototype was expensive and time consuming.

In the early nineties he decided to start work on the project using his own savings. He built the metal frame on which the cart would be mounted. But further development had to wait for lack of resources. In December 1993, he was invited by SRISTI to participate in its first Advisory Committee Meeting held at Indian Agricultural Research Institute, New Delhi. During that meet he was asked whether he had any new product ideas on which he wished to work on in the near future. Seizing the opportunity, Amrutbhai explained to them the idea of his improved bullock-cart. By that time he had already spent about Rs. 8000 on the project. The Committee members liked the idea and felt it was worth supporting. In due course he submitted a written proposal which was scrutinized by SRISTI and it was agreed that SRISTI would bear half the expense of developing a prototype of the new bullock-cart. If the new design proved successful and economically profitable, Amrutbhai would share part of the profits with SRISTI for a given period of time. This would enable SRISTI to help other innovators. If for some reason the design did not work out, the advance would be treated as a grant. His morale boosted, Amrutbhai discussed the plans for the new project with his sons Bharat and Ashwin, both of whom he had trained in the maintenance and development of farm implements. Over the years, Amrutbhai had come to rely on them for the day-to-day running of his enterprise.

As a first step towards the redesigning of the bullock cart Amrutbhai purchased a hydraulic jack with an accompanying tank from the nearby city of Rajkot. The tank was too large for the cart and so he procured another one of proper size. After filling it with the oil he applied pressure on it through a pump. The tank burst but fortunately no one was hurt. On probing Amrutbhai discovered that the tank had burst because its outlet was clogged. He realized that this line of thinking was not worth pursuing because, given the nature of their work, the farmers could not be expected to keep the equipment dust-free all the time. The use of such equipment could prove potentially risky for them. Nevertheless, he decided to give the original tank a fair trial. Despite three days of hard work he failed to make the cart lift up. Thereupon he decided to return the hydraulic system to the shop-keeper in Rajkot. The shop-keeper on examining the equipment found some minor defects. He offered to either replace the equipment or to return the money. Greatly relieved, Amrutbhai collected his money and returned home. The net damages were only Rs. 1600 which was the cost of the tank which had burst.

Many of the clients who came to the workshop saw the unfinished cart gathering dust. To some it seemed like an idea that had failed. But Amrutbhai strengthened his resolve to complete the project. He decided to work on it only in the peace and quiet of the night, when he could think and work undisturbed and test his new ideas without distraction. One night while at work he wondered if using a horizontal gear as a lifting device would solve his problem. Such a system was being used to lower an engine into a bore well. He decided to try it out and found that it was indeed effective in lifting the cart but not in lowering it. The failure of this experiment cost him another two thousand rupees. Not losing heart, he decided to try out vertical gears. At first he mounted two gears and found them successful. He then increased the number of gears to four, and then to six and finally to eight. It was the morning of New Year (2052 as per Hindu calendar) that he finally arrived at a satisfactory solution using eight gears. He named the new cart “Aaruni”, after the son of an Indian sage. Aaruni is well known in folk-lore for his example in checking the erosion of soil. By analogy, the new product would prove useful in checking the “erosion of the bullock’s strength”.

Pulley with stopper (1997)

In the villages, water is drawn from the wells, primarily for domestic purpose by the women folk. The originally designed rudimentary pulley system, which is also very physically demanding, is still in use for this purpose. Highly erratic rainfall, installation of submersible pumps and borings in arid areas, has lowered the water table further. This has compounded to the problems of drawing water from wells by means of a pulley. The problem, despite being very real and dangerous, was never taken up due to the apathy of the officials towards the affected group namely women and children. Realizing the importance of pulley in the daily routine of average rural women, Society for Research and Initiatives in Sustainable Technologies and Institutions (SRISTI) organized a workshop of artisans with proven capabilities to think scientifically and entrusted them with the responsibility to redesign the pulley to suit the women folk.

At the brainstorming session, Amrutbhai came up with a creative solution to this problem called pulley with a stopper His innovation ensured a safe method of drawing water from wells reducing injury and stress on the womenfolk. He called his pulleys the Ganga, the Yamuna and the Saraswati pulleys. Presence of a rachet on the pulleys prevents the movement of rope of these pulleys towards the well. In the Ganga, a ratchet type pulley, there is no loss of the rope and bucket. The Saraswati is a detachable pulley, which can be used at various locations where a beam is present. The Yamuna is a roller type pulley. Each costing under Rs 500, these pulleys are also economical to use. These pulleys were installed in several villages of Gujarat on an experimental basis and received good response from individuals and NGO's, though their diffusion somehow remained limited. Amrutbhai also got Gujarat Government’s Sardar Krishi Puruskar for this innovation. He has declared this technology as an open source technology for anyone to copy and make use of.

Passing on the genes

Amrutbhai has mentored his son, Bharat Agrawat (46) and fuelled his spirit of innovation. Bharat has come up with a number of innovations like a lemon cutter, innovative windmill for lifting water from wells, 5 HP power tiller cum tractor, which can be rotated at 3600 angles and many more equipments besides the modified stove. His multipurpose stove has two burners at different elevations to maximize usage of heat and can efficiently run using both, wood and coal as fuel. He first made an innovative windmill, which included weight balancing gearbox system, designed to pump water out of the well at a rate of 2000-2200 litres/hour and continues to come up with one thing or the other.

The Network Ambassador

Amrutbhai has been part of the Honey Bee Network almost since its inception and by far has contributed the most to sustain and nurture the spirit of the network. He has served the Board of SRISTI and contributed to its growth and expansion.

He has been instrumental in voluntarily organizing twenty Shodh Sankals in the Saurashtra region. To strengthen lateral learning among the grassroots innovators, the concept of Shodh Sankal-a chain of experimenting farmers, was initiated in mid 1990’s by SRISTI. This platform provides scope for lateral learning among those who solve the problem and not only those who merely articulate them. Shodh Sankals make use of a solution augmenting approach rather a simple problem solving one. Meetings are organized in different talukas where the farmers participate in large numbers. The meetings, whose main focus is discussion on organic farming experimentation, are now being organised by the farmers themselves at their own cost. Information on herbal agricultural products based on people’s knowledge is also disseminated during such meetings. These meetings have been a melting pot of innovative ideas from farmers and mechanics of the region resulting in a lot of knowledge exchange and problem solving.

A sizeable network of such people has been developed regionally by Amrutbhai, who accompany him to every Shodh Yatra (walk in search of local ingenuity), twice a year in different parts of the country. Amrutbai has participated in twenty six Shodh Yatras organized till date over the last fourteen years having missed only two of them.

Not satisfied with being just an innovator, Amrutbhai is also on a perpetual hunt for people like him, who have come up with creative ideas. All these years he has scouted about ninety six entries including engineering and herbal from his region and discovered about fifty innovators, farmers or traditional knowledge holders. Recently, NIF supported him for a workshop to continue his untiring work on innovations. An inclusive innovator, he has agreed to help and mentor any other innovator willing to make use of this facility. He has come up with the model of a small tractor within a few months of the support and is presently working the windmill with his son Bharat.

food processing machine| Pulley with stopper

Hailing from Malia in Junagadh district of Gujarat, Amrutbhai Agrawat (68) is not just another serial innovator but is also a great ambassador of the Honey Bee Network. A generous and benevolent soul, Amrutbhai is ever willing to voluntary help anyone needing his time or advice or even innovations.

A Pujari in a local temple, Amrutbhai began his life as a farm worker after discontinuing his studies in fifth class. He set up a small farm machinery workshop at his place and also started making iron doors, boxes for granaries and iron gates. His son, Bharat, a serial innovator himself and an awardee in NIF’s Fourth National Biennial Competition (2007), started helping his father when he was in the sixth standard and has since, continued his father’s legacy. For his pulley with stopper, Amrutbhai won a National Award in NIF’s First National Competition (2001) and also Wall Street Journal’s Asian Innovation Award in 2005.

A compassionate soul, Amrutbhai Agrawat has learnt to solve problems faced by farmers, women and labourers essentially through his own life experience. Hardship in his early life, created in him a desire to do something about the problems faced by common people. He innovated as many as seven different useful farm implements such as tilting bullock cart, groundnut digger, multipurpose toolbar, wheat sowing box etc.

Granted, Patent no. : 194420

na

na