Lemon Cutting Machine

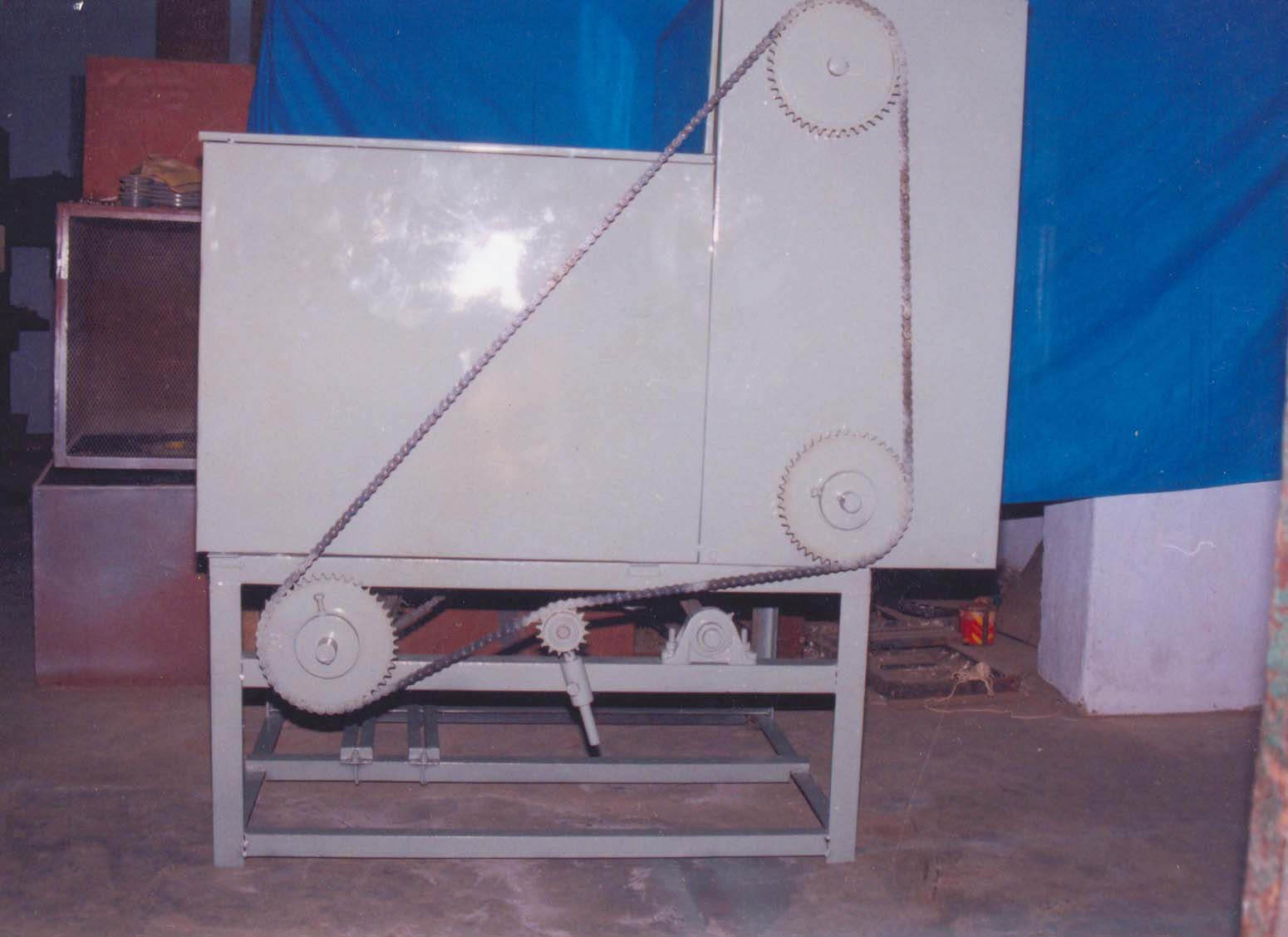

This innovative machine can continuously cut large quantities of lemon into required shapes and sizes. The machine includes two fixed hoppers - one conical and another circular, both having two outlets. When a taper disc, fitted in the circular hopper rotates, it makes the lemons move forward through a passage one by one. This passage is in the shape of a channel, which has the provision of a chain control regulatory mechanism in the centre. This serves as a gripping system and ensures the movement of lemons subsequently into the cutting system. Before the lemon is cut into eight pieces, there is a mechanical regulatory mechanism, which so opens and shuts the inlet chute that the lemons are cut in sequence. In the cutting chamber, the lemon is placed on the upper side of a multi edged cutter with four edges facing four directions and fixed in position.

Subsequently, a plunger, which is fitted above, moves vertically to press the lemon to the cutter and the lemon is cut without the shape being destroyed. The lemon is cut into four slices with a single stroke of the plunger and in the next movement there is a diagonal cut that divides one entire slice into two. Thus, a total of eight slices come through the outlet.

This machine is capable of cutting lemons ranging in size from 0.75 inches diameter to 2.5 inches diameter with the help of a spring loaded mechanism which also provides a better grip on the lemon which ensures uniformity in cutting. For packaging in smaller quantities, the lemon has to be cut into smaller pieces (12 to 16 pieces). Changes can be made in the present machine to do this as well as to grade the lemons. This results in lower cost of production.

Advantages

The slices of fruit produced by using this machine are of a uniform size and can be neatly and conveniently collected and recovered. Optimized power transmission ensures less consumption of electricity (7-8 units in 8 hours of operations). This device is labour saving - only one person is required to operate it. There is a minimal wastage of the lemons in the cutting operation i.e. 100% of the yield is utilized. The machine is compact and made of stainless steel, which makes the process hygienic. The half CAM lever mechanism in the machine ensures that the lemons are fed to the cutting chamber one by one to avoid cluttering and this ensures proper cutting of the lemons. The synchronization of the movement of the four-edged vertical blade and rotary horizontal blade ensures that the lemon is cut right across both the axes and this ensures removal of seeds without any effort. This feature not only saves manpower costs and wastage due to improper cutting, but also contributes to the quality of pickles (seeds in pickles often cause irritation to the consumer). The cutting capacity of this machine is 160 lemons/ minute or 450 kg per hour. This innovative technology has an edge over two other manufacturers, who make similar machines, in terms of the low initial investment (Price-Rs.100,000) and low operating cost. This machine is also easier to operate and maintain than existing alternatives.

From the social benefit perspective, the technology offers a less hazardous process for labourers, usually women, who spend a considerable amount of time in cutting the lemon manually to the required shape and size. They often suffer from blisters on the skin while handling lemons as these are highly acidic.

According to Nagarajan, the manufacturing cost of a single prototype is Rs. 82,000 inclusive of labour charges and other costs. His selling price is Rs. 95,000.

M. Nagarajan (45) lives at Usilampatti, a small village 40 km away from Madurai in Tamil Nadu. He has studied up to ninth standard. He is married and has two children. Being the eldest in the family, he supported the education of his younger brothers and sisters and also got them married. He is the sole bread-winner of the family. His dream is to develop such machines related to food processing which are not available in the market. M. Nagarajan has modified a garlicpeeling machine and a lemon cutting machine significantly. These improved machines address the two-fold problem of the pickle industry, namely, inefficiency due to low degree of automation and short supply of labour during peak seasons, which limits the capacity.

- Height – 40″ – Breadth – 30″ – Length – 40″

- Weight – Approximately: 350 Kgs

- Power – 220V – AC (2 HP) – 3 Phase or Single Phase

- Each piece of lemon is cut into 4,8,16 slices as per the choice

- Very Low Power Consumption.

- The machine is capable of cutting lemons ranging in size from 0.75 inches diameter to 2.5 inches diameter with the help of a spring loaded mechanism.

- The cutting capacity of this machine is 160 lemons/ minute or 450 kg per hour.

- The slices of fruit produced by using this machine are of a uniform size, and can be neatly and conveniently collected and recovered.

- Well optimized power transmission ensures less consumption of electricity (7-8 units in 8 hours of operations). It is labour saving -only one person is required to operate it.

- There is minimal wastage of the lemons in the cutting operation i.e. 100% of the yield is utilized

- The machine is compact and made of stainless steel, which makes the process hygienic.